Ikonart Stencil Kit | AU Plug No Adapter | Incl. Exposure Stand | Ikonart UV Exposure System | Australian Warranty

Includes Exposure Stand, Australian Plug & Warranty.

Ikonart USASKU: E-601

Create custom, reusable stencils with the revolutionary Ikonart Custom Stencil Making Kit. Using a pre-coated UV emulsion film eliminated many of the time consuming steps in screen making.

The Ikonart Stencil film is designed to make reusable, custom stencils at home in just three easy steps - print, expose, rinse! Ikonart Smart Screen Stencils are the fastest, smartest and easiest way to create reusable stencils and the kit comes with everything you need to get started. As long as you have a laser or inkjet printer, you can use our kit!

Manufactured to the highest industry standard in the USA, Iknoart films use a new improved trademarked photosensitive emulsion pre-coated evenly across the mesh.

- New coating keeps the mesh tight and straight

- New adhesive backed Stencil film for freehand printing

- 50% increase in film shelf life. Up to 18 months best before (film still does not expire at that time).

|

|

|

|

|

| Easy Artwork Creation | Fast UV Exposure | Simple Washout | High Quality Results | Quick Start Guide |

- Use your desiangs and artowrk, quickly and easily printed onto Artwork Transparencies (or hand drawn).

- No chemicals or diazo mixings, no coating emulsions onto a screen, plus no storing the mix (or desposing of the chemicals) after use.

- No time comsuming hand cuttings of films, that provide low quality results with no fine lines or graphics and bridges to lettering (army lettering)

- Fast exposure using a UV-A wavelength matched to the films emulsion.

- Fast washout without high pressure bays or equipment.

UV Exposure Lamp is Australian Certified (not US/UK model)

UV Exposure Lamp is Australian Certified (not US/UK model)

You can't put a price on safety . . . . well seems you can actually as that's why our kit costs more than other Ikonart kits you'll see online that will require a power adapter/converter to operate the US/UK wired lamp inside.

The SCREEN PRINTING SHOP UV Exposure Lamp is Australian PAT tested and certified with an Australian compliant hard wired plug fitted.

- Powerful 30W long lasting LED UV Lamp provides instant on with no replacement bulbs

- Australian hardwired plug with earth - no US/UK/110V adapter required.

- PAT Tested to AU/NZS 3760:2022 with tag.

- Energy efficient with low heat output - safe to touch.

- Long cord with in built on/off switch for easy use.

That small extra you pay over a non-compliant imported US kits using 110V Lamps, ebay or Amazon is for the Australian warranty and electrical testing it takes to ensure our products are safe.

Making Your 1st Stencil

Iknoart Film Exposure Guide

Iknoart Film Exposure Guide

Exposing your Ikonart Stencil Film works by using artwork to block the UV light, hardening the areas of the film that aren't blocked, and leaving the areas that are blocked water-soluble. Therefore, anything that will block the light from hardening the film can be used as "artwork".

First place to start is the Quick Start Booklet.

Ikonart Films are precoated with a UV emulsion which hardens when the correct wavelength of UV-A light is projected.

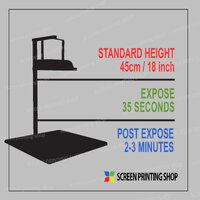

Our UV Exposure Lamp is supplied inside this Ikonart Stencil Kit and matched to the film's emulsion with the recommended exposure distances and times.

If your a visual learner, below is an introduction to the system. There's also a range of videos online, or go straight to the Exposure Cheat Sheet.

Use High Density Artwork

Use High Density Artwork

It is recommended Artwork Transparencies be used for all Ikonart Film exposures.

Do not use papers that will block the UV.

When you print your artwork, it is important that the black areas can block ultra-violet light and are 'high density'.

Toner that looks dense may actually be closer to translucent in its ability to block UV light. A simple test: hold the artwork up to a light source (sunny window, lamp, etc.). If you can see any light through the black areas, the artwork is not dense enough and will not produce a good stencil.

For an example of high density, hold a piece of black construction paper up to a light source. No light will bleed through. This is the density your artwork should provide.

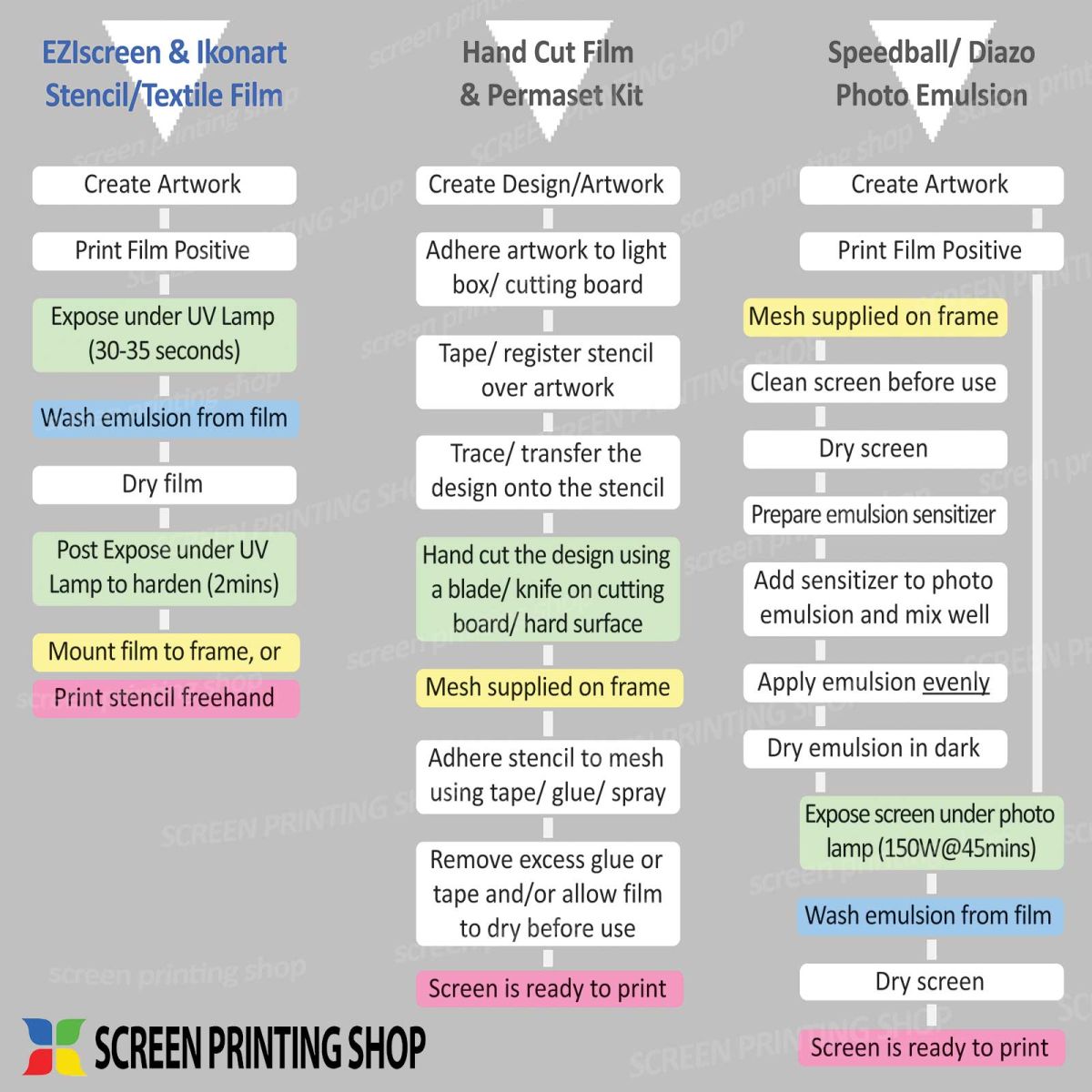

Compare Your Options

Iknoart films replaces many costs and time consuming steps involved in creating a traditional emulsion screen, in addition Ikonart offers superior detailed results over chunky hand cutting stencils. Ikonart offers file lines & solids without the emulsions and coatings as the film is supplied pre-coated for you.

Here's a quick comparison:

Beginners often don't realise there are many steps involved in creating an emulsion screen using Diazo's and/or mixtures to pre-coat the screen before you even begin.

Beginners often don't realise there are many steps involved in creating an emulsion screen using Diazo's and/or mixtures to pre-coat the screen before you even begin.

It is a long timely process, made even longer without purchase of additional equipment including a emulsion scoop coater and frame drying racks.

Of course your also handling chemicals and need to work away from children and others if doing this at home - remember you can't wash the chemicals down the drain - dispose of them properly.

Hand cut stencils are very cheap and most commonly purchased as a first attempt in a craft/ art shop . . . however the very low lever of quality obtained isn't understood (as unless your a very experienced expert with a cutting knife) hand cutting does not allow fine graphics, no shading, no fine lines and all words/text require bridges in the design (army style lettering).

Design options with hand cutting is VERY limited. They are cheap to use that's why they are so attractive in the store.

There's also the added step of attaching to a silk screen for printing, as if not adhered correctly the stencil will peel off/tear, ruining all your hard work.

You can compare the systems and costs for yourself, we would expect you too, just remember to include all the costs and equipment you will really need to make a screen and importantly the time it is going to take you. Time is money if your selling your printed items.

Next Step Up: RISO MiScreen Digital Screen Maker.

If the above still seems a bit complicated for you, then you may have larger requirements and need to step up to the next level of screen making systems.

Computer artwork is digitally transferred directly onto the screen mesh ready for printing - no artwork films, no exposures, no water washout.

It's a more expensive system using new technology and designed for home & small business customers, the Digital imaging system offers near instant screens at lower costs. You can explore more in the MiScreen menu on the website.

|

Our new and improved kit is made of lightweight metal and has a smaller footprint than our original Ikonart Kit. Check out the features of the new exposure stand vs the old exposure stand. |

||

|

|

||

Kit Contents

Exposure Stand (dimensions when setup 14" W x 14" L x 18.5" H).

UV LED Exposure Light - 230V Australian PAT Tested & Certified.

5 x Ikonart Stencil Film 10x12" sheets (Made in the USA)

2 x Clear Exposure Sheets (inside combo film packet)

5 x Inkjet Printer Film (8.5" x 11" Made in the USA)

5 x Laser Printer Film (8.5" x 11" Made in the USA)

Ikonart Clipboard for washouts

Ikonart Plastic Squeegee

Exposure Stand Setup Guide

Quick Start Guide

| SKU | E-601 |

| Barcode # | 9334315037392 |

| Brand | Ikonart USA |

| Shipping Weight | 3.6000kg |

| Shipping Width | 0.420m |

| Shipping Height | 0.100m |

| Shipping Length | 0.380m |

| Shipping Cubic | 0.015960000m3 |

| Unit Of Measure | Set |

| Type | Made in USA, Converted In Australia |